Source: cincinnaticonvertors.com

When running a flexible packaging printing business, it is important to be well informed on the processes you should engage in. Investing in this knowledge will expose you to new technologies and methods of improving your printing processes. This will go a long way to ensuring that your processes are more effective and that you get the best results each time. When it comes to printed flexible packaging, you have a few printing options to choose from. Some of these printing types include:

Table of Contents

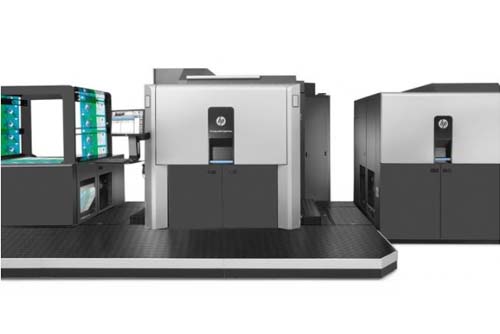

Digital Printing

Source: www.labelsandlabeling.com

Digital printing employs the use of an inkjet printer that is quite easy to use even as a beginner in the industry. This digital printing process allows graphic elements to be applied on a plastic substrate without having to invest too much time. This process comes in handy when working with flexible packages. They are easy to work with and can easily be printed on with a few clicks of a button. This process comes with great advantages that as a manufacturer you should consider. Some of these benefits include:

- Minimal setup costs especially since the only thing you need to invest in is an inkjet printer.

- Low wasted materials. This is mainly because mistakes are not easily apparent when using this method. This allows you to avoid wasting any flexible packaging materials.

- High printing quality. Compared to other processes, this printing option offers very high-quality results. It is more intricate when it comes to the designs and graphics being printed on the flexible packages.

- Faster turnaround time. When it comes to using this option, you can be sure that your processes will be faster. This will allow you to deliver to your clients faster.

On the other hand, you also find that the digital process also features a few disadvantages. They include:

- Large scale printing is more costly. Given the intricate process that is followed when printing digitally, you find that doing it in large volumes becomes harder. This printer is meant to work with one at a time. With this, the price of producing printed flexible packages in bulk becomes very costly.

- Limitation in ink choices. Digital printing does not allow you to use as many colors as you'd like. This is especially true when dealing with metallic colors.

Flexography

Source: www.germark.com

Flexography is the most used printing solution by manufacturers in the industry. It features a flexible plate that allows it to easily print on products. The flexography process is applied in printing the most flexible packaging options given that it offers great advantages. Some of these advantages include:

- Offers versatility. This option allows the manufacturer to either use water or oil-based inks. Having this option gives more versatility when it comes to the looks that are achieved on the flexible packaging.

- Quick turnaround time. With this printing option, you also get to deliver to clients a bit faster.

- It offers a lower cost when tooling which allows you to start without investing a lot of money.

However, this option also has a few disadvantages that you should consider. They include:

- Lower print qualities. The flexography method offers a lower print quality compared to using the digital option.

- Problems with multicolored printing. This method may prove to be a problem when it comes to printing using more than four colors. This means if the design you're working with features a lot of colors, you'll have to look for a different option.

- Low photo quality. If you'll be including photos on a flexible package, using this method will not give you the best outcome. The photos produced during printing are not as clear and convincing as they should be.

Rotogravure

Source: insights.risiinfo.com

This process involves engraving graphics on a plate that is then used to transfer the results onto the flexible packages. The Rotogravure process has to be done using an image carrier to ensure that it turns out as it should. This process is commonly used on Boxes and flexible packaging like stand up pouches. Using this printing method offers the following advantages you should consider.

- Quality photo images. Given that rotogravure features engraving graphics, photo images are also printed in higher quality. This allows the user to easily identify the photos without any struggles.

- Allows the use of more than 4 colors compared to flexography.

- Printing cylinders used in the printing process are made to last longer. This allows the clients to create more flexible packaging options without spending money on another printing cylinder.

- High print quality. When it comes to the print engraved on the flexible packages, it appears with a higher resolution compared to other processes.

Some of the disadvantages associated with this printing method include:

- Minimal Coating Options

- High initial investment. With this process, you'll need to invest a substantial amount of money when it comes to tooling.

- Not suitable for small scale productions. Given the investment required when getting started with this process, printing a few packages is not advisable. You need to ensure that you are printing in high volumes.

Lithography

Source: www.artprintsa.com

The lithography method involves the use of a lithography plate and graphics made of oil. These graphics are transferred on to the plate to make it easier to print on packages. Before the printing is done, the plate is first treated using acid. This ensures that the printing process goes on smoothly. The Lithography process is however more complex compared to the other printing methods. Some of the advantages that come with Lithography include:

- High printing quality

- Application of more than 4 colors with the addition of 2 PMS colors.

- Ability to use special coating for glossy or matte flexible packages.

- Offers a smooth color transition in the graphics and prints used.

Like any other printing method, lithography also comes with a few disadvantages. They include:

- Longer lead times.

- Limited flexibility in the process.

- High minimum order quantity.

- Results in a costly tooling investment.

How Flexible Packages are Printed

Source: www.tweakbiz.com

When it comes to printing flexible packages, the first thing is to get the design specifications in check. These specifications are provided by your client to ensure that you stay on track and deliver what they want. Paying attention to this ensures that you do not have any conflicts or wasted material.

Once you have the designs ready, the cylinder printing process begins. This cylinder is very important given that it gives you the dye or ink you’ll use in printing. Each cylinder is meant to provide a certain color that you can work with. This means that you need to ensure that you have all the colors in mind. This will also help you decide on which printing process you’ll work with.

After this, the printing cylinders are then loaded onto the printing machine to begin the printing process. Once the printing cylinders are in place, the transparent polyester or material you’ll be using is loaded. After everything is in place, the printing process can then begin. If you’ll be using different plates for this, you can be sure that they’ll yield different results.

Once you are done with the printing process, you can then load the material onto the flexible packaging machines. This will result in different packaging options depending on what your client was looking for.

Conclusion

When it comes to running a printing business, you need to ensure that you stay up to date. This is mainly because technologies change regularly which is a great thing. Paying attention to this will allow you to invest in the right machines for your needs. All the different types of flexible packaging printing have their advantages and also disadvantages. Also, they feature a variety of options when it comes to the tooling and processes that you can use. Understanding the printing process is quite easy provided you follow the steps associated with the type of printing you choose.